News

Process engineering team works with challenging technical problems

15.12.2022

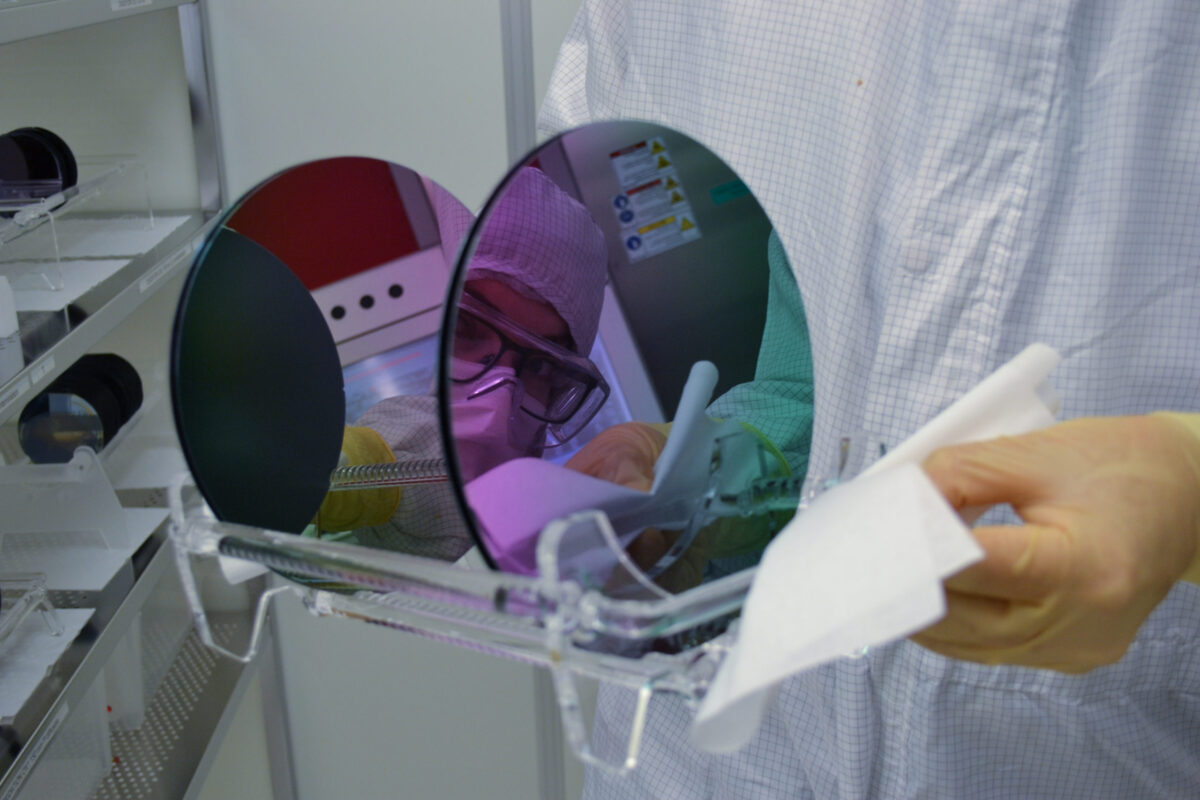

“I just love thin film and semiconductor processing. It has been 15 years of my life,” says Peter King, Head of Process Engineering at KYOCERA Tikitin. He has worked, among other things, as an Atomic Layer Deposition (ALD) researcher at the University of Liverpool, Newcastle and Helsinki. Before his current position, he spent over three years at ALD technology company.

Ten years of research work in the academic world have provided King with a strong foundation to work as the head of KYOCERA Tikitin’s process engineering team .

Development of the whole manufacturing process

The Process engineering team has been expanding to meet demand for a few years and during that time has grown from a couple of people to the current ten experts.

These specialists have a very wide range of backgrounds of knowledge and skills. People come from many countries: Finland, United Kingdom, Pakistan and India.

“Our core task is managing the device wafer process. More broadly we can support the whole manufacturing process from precuring the substrates at the beginning, pretreatment, the whole silicon-based MEMS process and even dicing and separation. On a 150-millimeter wafer you can fabricate tens of thousands of devices. We treat them as products, so they can be separated and tested. At this stage we still do research and development to optimize the products”, King describes process engineering team’s everyday work.

The process engineering team works on production process research and product development in close cooperation with subcontractors and partners. The starting point of the team’s work is always the desired product, which defines the production process down to fine detail.

Close to ramped up

KYOCERA Tikitin is currently in an interesting phase, because it is close to production of its first products. This puts pressure on the process engineering team.

“We have incredibly tight time frames when things must be completed. We really like to try to think the quality of production in our minds when we do our job.”

The development of both the product and its production process is accompanied by excitement every day, which King finds very motivating.

The team’s pressure has been somewhat eased by hiring a couple of new experts to the team at the end of the summer 2022. It now takes time to train them before they can take full responsibility for the development processes.

”As our production is ramped up and production support is needed, there will be a lot more demand. We need to do more wafer starts and get fabrication done quicker.”

At the best case the new employees have worked with similar equipment and processes that KYOCERA Tikitin uses in their previous positions. In this case, the training of new experts can be very efficient. On the other hand, the company is also happy to hire experts not previously based in the field and train them for their tasks. Fresh insight from other specialty areas can add value to the team and enable new ideas and problem solving avenues.

“This is highly technical work. There is a huge learning curve for everyone, including me!”, King says. Basic education level needed is Masters or PhD degree.

“The core skill set and knowledge is material science and the wafer level device processing, thin film processing and lithography. Special skills are also needed for example failure analysis. People with knowledge of front-end processing, MEMS processing and post-processing like finishing and back-end processing are also what we are looking for.”

Always as a team

The process engineering team solves demanding technical problems, often under the pressure of tight schedules. How does team spirit withstand such pressure?

Six months leading his team have shown King how well people support each other in challenging situations. No one is left alone and information is widely shared.

“Everything we do, we do as a team. Together we solve problems and together we celebrate success. I’m really inspired how everyone backs each other up.”

“You get to work with amazing people!”

Because the team is working on demanding technical problems, learning together is part of everyday work. This has also been the case for King. Personal development goals have been made for each employee, implemented regularly. These developing supporting processes come from the acquired company’s approach to employees.

“The KYOCERA company has a strong culture that emphasizes the employee’s personal responsibility for both their own development and the success of the company. We encourage people to think about their own development and their own career, how they could advance and develop in different positions”, King says.

When King sums up the reasons for joining KYOCERA Tikitin’s growing group of experts, he brings up the team first.

“Joining KYOCERA Tikitin firstly means that you get to work with amazing people. The second reason to join is this amazing time, when we are just accelerating toward the goals we have as a company. The third is the fact that we are all learning together every day.”